| Wire Cloth | Stainless Steel Wool | Copper Wool | Mist Eliminators |

Calendared Wire Cloth

Passing wire cloth between heavy rollers, which has the effect of flattening the high points at the intersection of the wires. Thereby reducing the thickness of the wire cloth and giving the material a smooth surface.

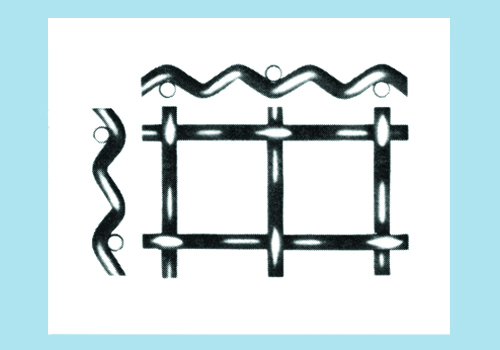

Crimp

Corrugations in wires to permit locking them in place when perpendicular to each other.

Mesh

The number of openings per lineal inch of wire cloth, measured from the center of a wire.

Micron

1/1000 millimeter, 0.00003937 inch.

Open Area

The ratio of the area of the open spaces between the wires to the total area of a piece of wire cloth, expressed as a percentage.

Opening

The clear space between adjacent parallel wires. Not affected by diameter of the wire.

Shute Wires

The wires running the width of wire cloth, perpendicular to the warp wires.

Warp Wires

The foundation wires running the length of wire cloth.

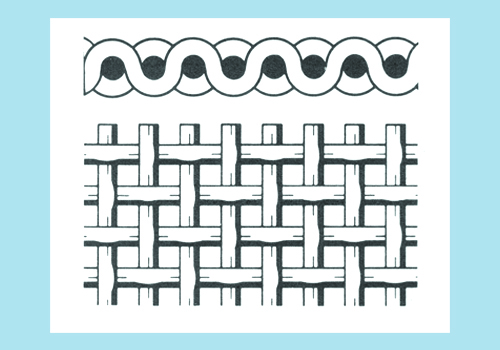

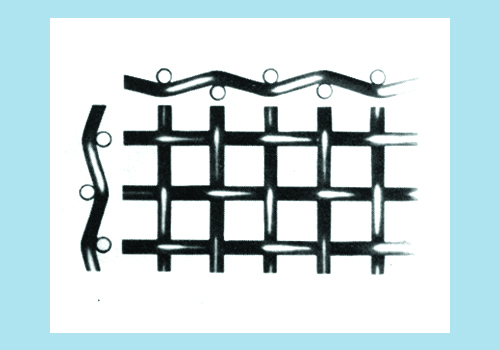

Wire Cloth woven so that each shute wire passes alternately under and over successive warp wires and each and under successive shute wires.

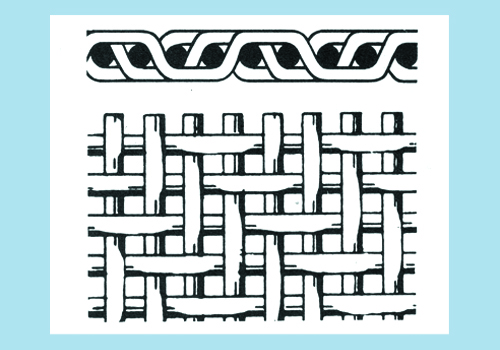

Warp wires are generally larger than the shute wires. The shute wires closely spaced to provide a dense weave with wedge shaped openings.

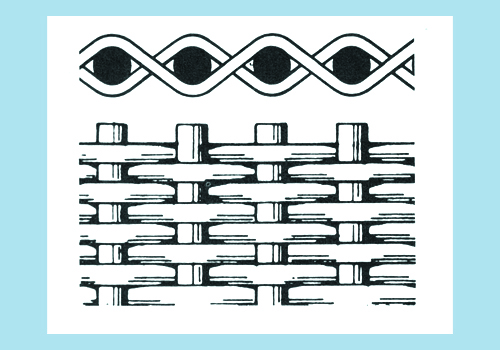

Each warp wire and each shute wire pass successively over two and under the next adjacent pair of wires. It requires less bending of the wires than plain weave, allowing the use of heavier wire for a given mesh.

Similar to twilled weave, except that the warp wires are heavier than the shute wires.

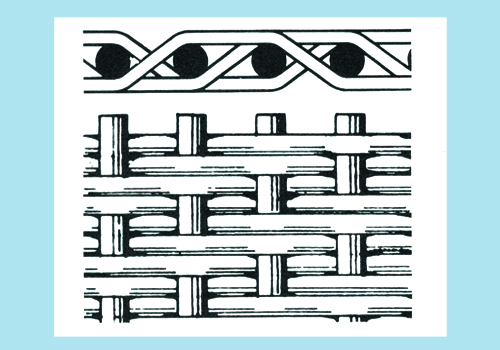

Crimps at points of intersection in both warp and shute wires to lock wires in position.

Additional crimps between the normal crimps at intersection, which have the effect of making the wire cloth more rigid and the spacing more accurate.